LUBE INDUSTRIES Srl Via dell’industria, 4 - Treia (MC)

Kitchen cabinets, OLTRE NECK

This product data sheet complies with the specifications set out by Italian Legislative Decree no. 206 dated 6th September 2005 "Consumer Code".

Door consisting of a poplar chipboard panel support (compliant with E1 and EPA TSCA Title VI), 22 mm thick, veneered in old European oak and trimmed on 4 sides in single-layer, brushed, European oak veneer, 1 mm thick; all glued with thermosetting, polyurethane adhesives. The finish is matt and can have a vintage material effect or combed effect.

As doors.

In aluminium with brushed Brill finish, stained Titanium, stained Urban or matt powder-coated aluminium in the following colours: black, amber, Dalvia, Tuscan red, misty grey, pure white, aquamarine, water green, Positano green , beaver, lichen green, Bromine grey, smoke, warm white, pink quartz, cadet blue.

22 mm thick door consisting of a chipboard panel support (class E1) covered externally with Fenix® laminate, 9/10 thick, internally with a laminate matching the exterior, 9/10 thick; trimmed on four sides in polypropylene, 1 mm thick, with laser gluing.

As doors.

In aluminium with brushed Brill finish, stained Titanium, stained Urban or matt powder-coated aluminium in the following colours: black, amber, Dalvia, Tuscan red, misty grey, pure white, aquamarine, water green, Positano green , beaver, lichen green, Bromine grey, smoke, warm white, pink quartz, cadet blue.

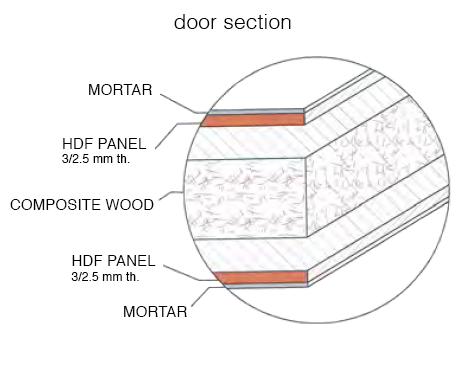

22 mm thick door consisting of a chipboard support lined on two sides with HDF panels (class E1), covered with mortar obtained from a mixture of various mixes, hydraulic binders and inert materials, with a quartz powder base and mineral sand with controlled granulometry, exempt from salts and impurities. To avoid temperature changes or particular dynamic stresses causing cracks or twisting, a percentage of elastomeric stabilising polymers are added. Expert craftsmen apply the skim coat on the panels strictly by hand and, once dry, the surface is coated several times with transparent acrylic whose function is to protect the panel against infiltration and dirt. Small holes, uneven spatula marks and not perfectly square corners should not be seen as defects, but as details of the door that enhance the craftsmanship of the work.

As doors.

In aluminium with brushed Brill finish, stained Titanium, stained Urban or matt powder-coated aluminium in the following colours: black, amber, Dalvia, Tuscan red, misty grey, pure white, aquamarine, water green, Positano green , beaver, lichen green, Bromine grey, smoke, warm white, pink quartz, cadet blue.

Door consisting of a medium-density fibre panel support (class E1), 22 mm thick, lacquered with white polyester resin-based primer and painted with polyurethane paint catalysed with non-yellowing isocyanate (lacquered finishes free from chrome, lead and cadmium). Available in several brushed glossy colours and matt colours with “soft” finish.

As doors.

In aluminium with brushed Brill finish, stained Titanium, stained Urban or matt powder-coated aluminium in the following colours: black, amber, Dalvia, Tuscan red, misty grey, pure white, aquamarine, water green, Positano green , beaver, lichen green, Bromine grey, smoke, warm white, pink quartz, cadet blue.

The frame is an extruded aluminium profile, 22 mm thick, with matt finish powder coating, matching the glass, honeycomb in the rear part with an ash grey MDF panel. A bright, 4 mm thick, extra-clear, smooth or satin-finish tempered glass pane is glued to the front and painted on the inside with various water-based colours.

As doors.

In aluminium with brushed Brill finish, stained Titanium, stained Urban or matt powder-coated aluminium in the following colours: black, amber, Dalvia, Tuscan red, misty grey, pure white, aquamarine, water green, Positano green , beaver, lichen green, Bromine grey, smoke, warm white, pink quartz, cadet blue.

The frame is an extruded section in 6060 aluminium, 22 mm thick, powder-coated in black or in the “Urban” finish obtained by means of a chemical oxidation process; a panel is inserted in the frame consisting of:

The frame is an extruded profile in aluminium, 22 mm thick; a drawn metal sheet is applied on the front part of the door and a filler panel in aluminium on the back. To make the door durable and light, sound-proofing and heat-insulating material is inserted into the cavity between the two sheets. The black or titanium finish, is achieved with a single anodic bath.

Door consisting of a panel, 22 mm thick, veneered with brushed, textured oak finish and vertical grain, with or without knots, or also with semi-open pore and vertical grain without knots. A strip of wood or metal, 1 mm thick, is placed between one trimmed slat and the next. The slats are joined manually with the related strips, one-by-one in sequence. The edge is made of solid 10/10 oak on the 4 sides, of which 2 width sides are with transverse grain and 2 height sides with longitudinal grain, with inlay. Available in various colours.

Door consisting of a panel, 22 mm thick in certified MDF (conforming to the US regulations: CARB ATCM PHASE 2 and EPA TSCA TITLE VI), lacquered in oxidised liquid metal: this is a craft product, which is produced with cold rolling through the application of liquid metal (brass and copper), on which special reagents are oxidised, then protected with a specific application for metals. Metals are live elements and the chemical corrosion procedure causes a more or less significant effect which cannot be considered a defect.Available in various colours.

Door consisting of a panel, 22 mm thick in certified MDF (conforming to the US regulations: CARB ATCM PHASE 2 and EPA TSCA TITLE VI), lacquered with semi-gloss oxidised metal effect: this is a craft product, which is produced with a lacquering process followed by manual tamponade to replicate an oxidised effect. This process causes a more or less significant effect which cannot be considered a defect. Available in various colours.

Door consisting of a panel, 22 mm thick in certified MDF (conforming to the US regulations: CARB ATCM PHASE 2 and EPA TSCA TITLE VI), lacquered with marble effect: for this type of door the eighteenth century marble effect technique is used. For the first process on the door in MDF, a watery mortar is spread to create the textured effect of the product and then a skim plaster is applied manually. At this point, it is subjected to a water-based paint cycle (white or light grey) and the manual reproduction of the marble vein on the planar side and on the edge of the door. When these phases have been completed and sufficient time has been given for drying, various coats of transparent acrylic are applied in order to protect the door against dirt and grease infiltration. Available in various colours.

Door consisting of a panel, 22 mm thick in certified MDF (conforming to the US regulations: CARB ATCM PHASE 2 and EPA TSCA TITLE VI), lacquered with matt leather effect in relief in various colours.

As doors.

Consisting of 18 mm thick melamine-faced chipboard panels in accordance with the US EPA TSCA Title VI standard (with very low formaldehyde emission).The shelves are 18 mm thick and equipped with built-in shelf supports with locking device. They can also be made of tempered glass (6 mm thick), grounded on the edges.

Edge in ABS or Polypropylene (PP) glued with thermosetting polyurethane glues 1 mm thick on the front parts of the unit sides and shelves and 0.5 mm thick on the lower and upper parts of the unit sides and on the sides and rear part of the internal shelves. Made of paper for the non-visible parts of furniture (back).

Consisting of 2.8 mm thick high-density fibre panels compliant with E1 and US EPA TSCA Title VI for formaldehyde emissions, wall units with polypropylene veneers and painted bases and columns.

Laminate worktop: 38 or 58 mm thick water-repellent wood particle board coated with high pressure laminate (HPL). For worktops in other materials, please refer to the "Useful information" section.

In sheet 18/10 stainless steel made using a single-casting or electrically welded tubs, with a smooth or "embossed" finish. For sinks in other materials, please refer to the "Useful information" section.

Faced bracket: melamine faced wood particle board panel (class E1); ABS edging.Veneered bracket: wood particle board panel (class E1) veneered with "slices" of wood (which vary depending on the model) and lacquered using acrylic/polyurethane products.

In pine wood or MDF (class E1) veneered with "slices" of wood (which vary depending on the model); acrylic/polyurethane lacquering.

In chequered aluminium or lacquered plastic to protect the sink unit from water seepage.

In knock-resistant plastic material (PVC) and height-adjustable, these are screwed to the bottom of the cabinet using special bushing, without requiring any drilling in the lower part of the casing (thus completely avoiding the creation of areas in which dirt may accumulate or through which water could leak into the base and sink cabinets).They are also available in aluminium and can be adjusted and mounted on a special base structure (also made using an aluminium profile).

These elements may be made using anodised or lacquered aluminium, or PVC coated with decorative melamine foil, and have a rubber seal at the top and bottom.

In rigid plastic material (PVC), drilled in the centre to allow any leaking water to escape and to protect the main cabinet column.

In aluminium or rigid knock-resistant PVC with laminate decoration.

In sheet steel and zamak alloy, copper-plated and nickel-plated for resistance to corrosion; adjustable in three directions.

The structure may consist of a 16 mm thick wood particle base (extremely low formaldehyde emission) faced in grey laminate with side and back panels in galvanised and lacquered sheet steel for protection against corrosion. Alternatively the structure can be made entirely of solid ash and plywood; sliding takes place by means of total extraction runners with a grooved system for anti-detachment locking and automatic closure which is activated in the final 4 cm. The soft-close system (blu-motion) is also supplied as standard.

In electrically welded metal wire; they may be plasticised with polymer resin, nickel-plated or chrome-plated and coated with a transparent plastic sheath (Crominox finish).

Top: may be a wood particle panel (class E1) coated with HPL plastic laminate (see laminate worktop) or veneered with "slices" of wood and lacquered with water-based, polyurethane or acrylic shades, or it may be made using glass, granite or natural stone.Borders and base structure: these may be made using metal or plywood panels, faced or veneered with "slices" of wood (these vary depending on the model).Legs: these may be made using metal or solid wood; lacquering is carried out using acrylic/polyurethane products.

Structure: this may be in tubular metal lacquered with thermosetting powders, or in solid wood lacquered using water-based (impregnating) and acrylic/polyurethane products (base).Seat and Backrest: these may be made using synthetic material (methacrylate), solid wood, plywood, upholstered fabric or simulated wicker.

Note: each type of chair or table is identified at the site of purchase by the relevant adhesive label on the packaging.For further information, please check the user and maintenance manual provided by GRUPPO LUBE.

For further information, please check the user and maintenance manual provided by GRUPPO LUBE.