LUBE INDUSTRIES Srl Via dell’industria, 4 - Treia (MC) - Italy

Kitchen cabinets, ANITA model

This product data sheet complies with the specifications set out by Italian Legislative Decree no. 206 dated 6th September 2005 "Consumer Code".

32 mm thick framed door with central panel, all in solid chestnut wood. The painting is done with a mixed water (patina) and solvent cycle, with an antiqued and brushed transparent colour and finish and matt gloss (10 gloss units) with a walnut, honeyed chestnut, antique white or green or plastered chestnut effect.

As for solid doors.

Frame same as doors, with a tempered, 4 mm thick, antiqued or Gotik finish.

Handles can be in metal and zamak alloy with galvanic bath, antique brass finish, antique silver, satin nickel, matt black, lead effect, copper, bronze or in terracotta or ceramic with different decorations.

Structure made with a Folding process (process carried out on the panels to obtain boxes and structures with edges from a single panel without edging) on 25 mm thick panels in composite wood veneered with oak and edged on the front with 0.6 mm thick oak. Internal shelf same as the structure edged only on the visible side with 0.6 mm thick oak. Back in 6 mm thick poplar plywood with low formaldehyde emissions (E1), veneered with oak. The whole thing is painted the same as the door.

Drawer made of 18 mm thick panels in composite wood plated with laminate (internal and concealed parts). For the visible parts and the front frame applied to the box a poplar plywood with low formaldehyde emissions (E1) is used, 18 mm thick plastered with quartz silicate water-based paints, to give a masonry effect (on the frame of the front, approx. 5 cm, around the door) in two finishes: roller and plastered. Internal shelf same as the structure edged only on the visible side with 0.5 mm thick ABS. Back in 6 mm thick poplar plywood with low formaldehyde emissions (E1), veneered with oak.

The internal structure is made of solid beech panels painted with water-based paints. The drawers slide on full-extraction runners with an interlocking system that prevents going off track and auto-close system engaged in the last 4 cm. In addition, a slow-close system (blu-motion) is supplied as standard.

Made with 38 mm thick panels in composite veneered wood same as the door and edged with 0.6 mm thick wood same as the door. The whole thing is painted the same as the door.

Tiled backrests have a 12 mm thick poplar plywood panel compliant with the E1 standard (with low formaldehyde emissions) and a 10 mm thick ceramic or natural stone decorative panel. The decorative panel is secured with transparent polymeric silicone. The joints are sealed with a dual-component waterproof epoxy, bacteriostatic, fungistatic, resistant to abrasion, acids and stains. All elements are treated with a stain-resistant protective product for stone and porcelain stoneware.

Tiled worktops have a 30 mm thick spruce plywood panel compliant with the E1 standard (with low formaldehyde emissions) and a 10 mm thick ceramic or natural stone decorative panel. The decorative panel is secured with transparent polymeric silicone. The joints are sealed with a dual-component waterproof epoxy, bacteriostatic, fungistatic, resistant to abrasion, acids and stains. All elements are treated with a stain-resistant protective product for stone and porcelain stoneware. For worktops in other materials see useful information.

Made of 18/10 stainless steel sheeting, single mould or with electro-welded bowls, smooth or "embossed" finish.

For sinks in other materials see useful information.

Made of fir wood (class E1) veneered with ash and painted same as the door.

In shockproof plastic (PVC) material, adjustable in height, the feet are screwed into the lower part of the cabinet by means of special bushings without drilling through the bottom (thus completely avoiding points where dirt can accumulate or water can seep into the drawers and under sinks). They can also be made of aluminium, adjustable and mounted on a special base also made of aluminium.

Poplar plywood panel veneered with ash (class E1) painted with anti-yellowing acrylic/polyurethane products.

Poplar plywood panel (class E1) with a hole in the centre to allow water to drain and to protect the unit's frame.

Made of fir veneered with ash and painted with acrylic/polyurethane anti-yellowing products.

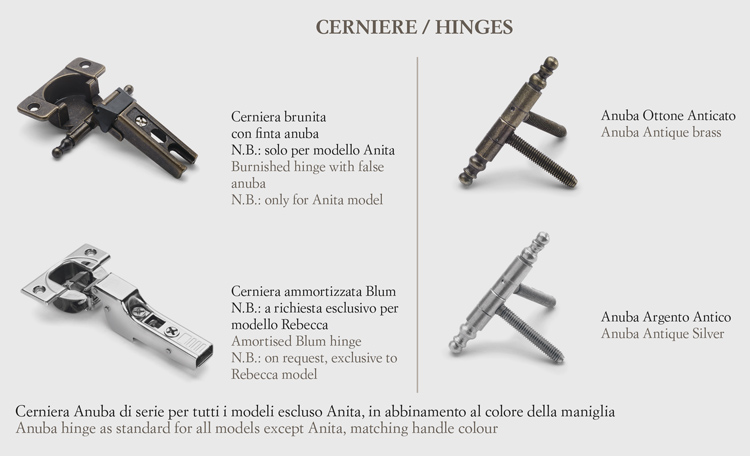

Metal, they can be: simple "Anuba" type (a device made up of two elements rotating on a central pin, with one part anchored to the main structure and the other to the door) or "fake Anuba" with half stop (only for the Anita model) with burnished finish and adjustments in the three directions, or overlay with half stop nickel-plated anti-corrosion with adjustment in the three directions and soft closure (only for Rebecca model).

In stainless steel (AISI304 or AISI430), completely recyclable.

Worktop: wood veneer or in solid wood of various species and painted with water-based, polyurethane or acrylic anti-yellowing colours. Base and strips: in solid wood or veneered with different woods depending on the model. Legs: solid wood, painted with anti-yellowing acrylic/polyurethane products.

Structure: solid wood painted with water-based (impregnating) and acrylic/polyurethane (base) products. Seat and backrest: in solid wood or faux straw.

Note: each type of chair or table is identified at the site of purchase by the relevant adhesive label on the packaging.

Funnel made of 12 mm thick plastered plywood panels (see visible parts of bases/columns). Solid wood panel same as the door, painted same as the door. Lower panel in 18 mm thick composite wood veneered and painted same as the door.

For further information, please check the user and maintenance manual provided by GRUPPO LUBE.